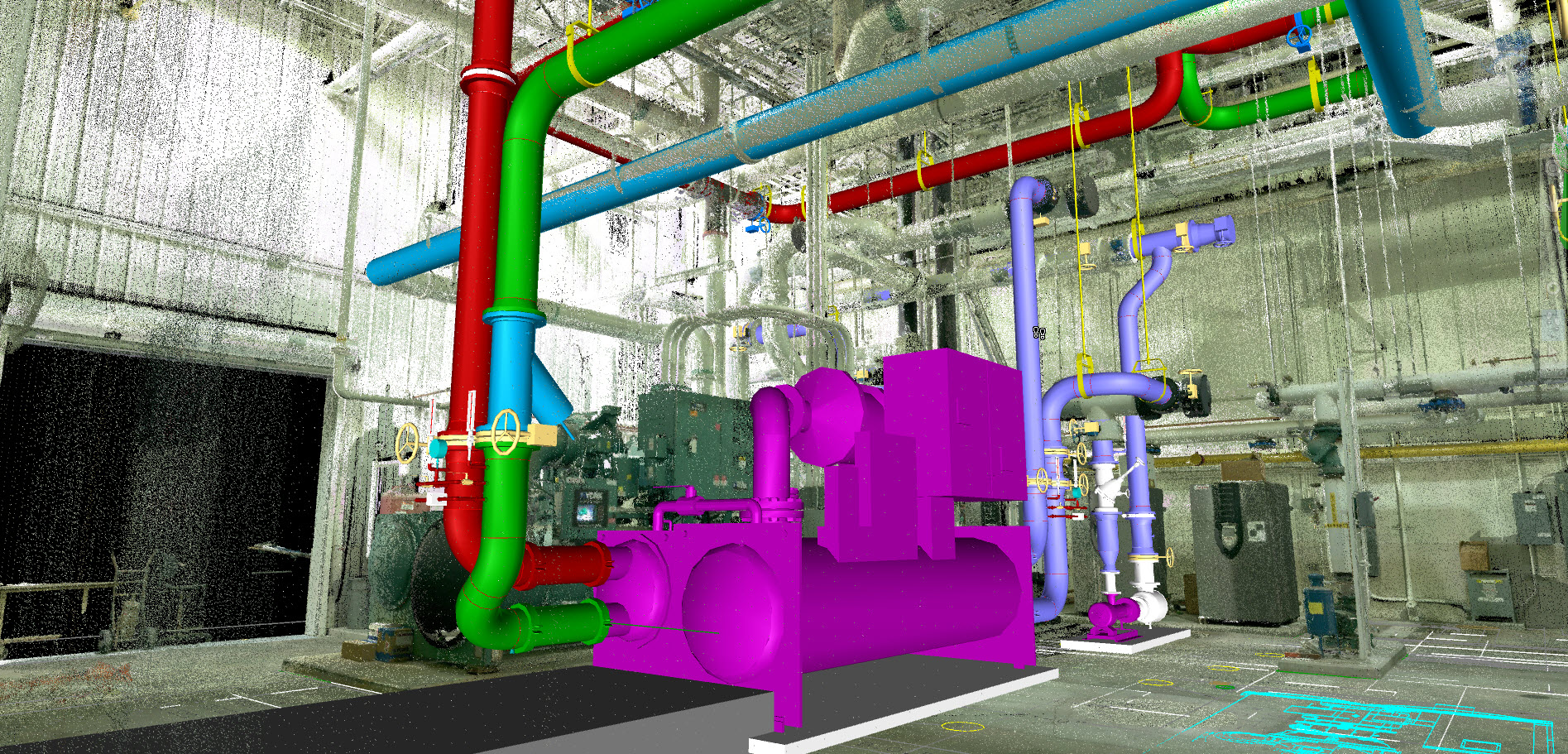

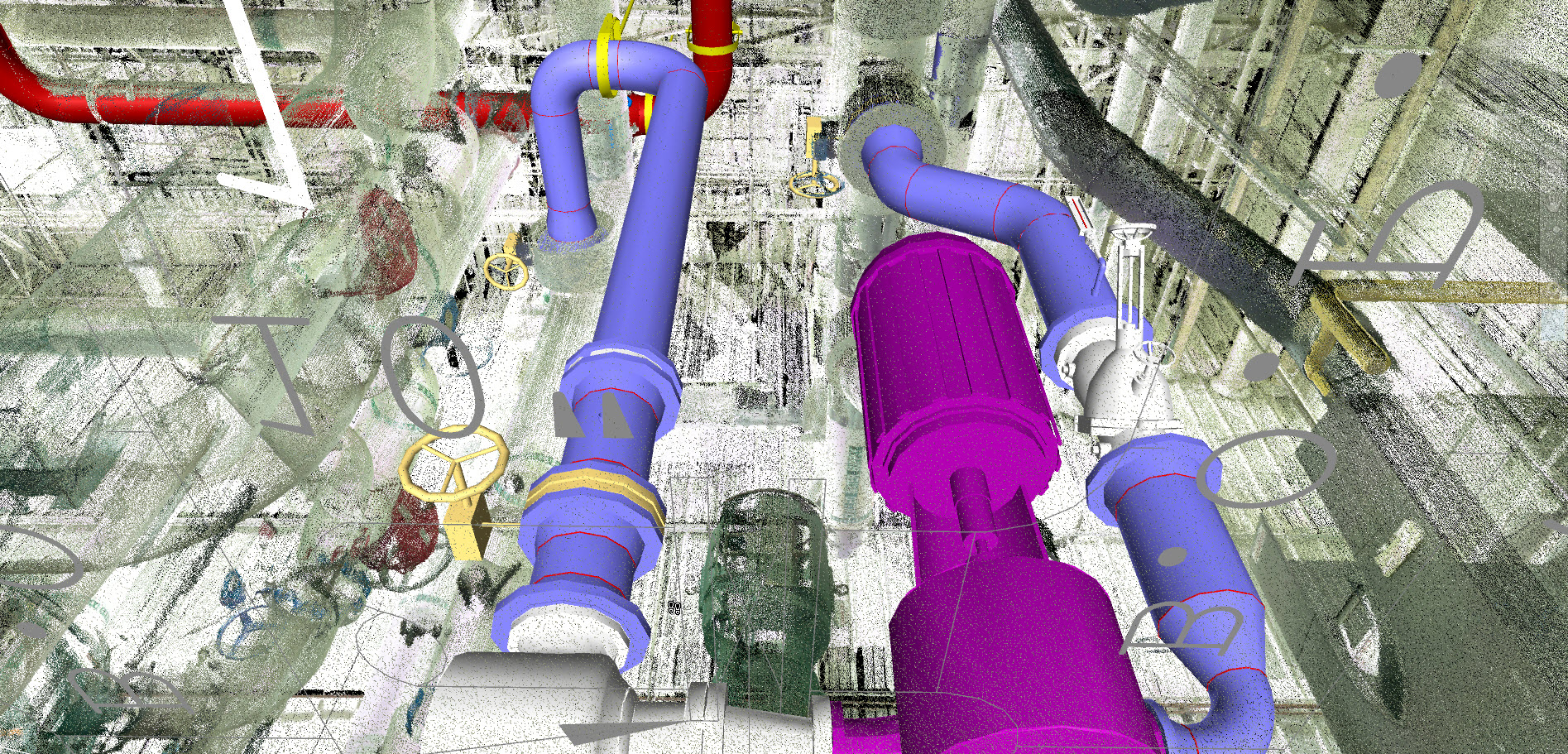

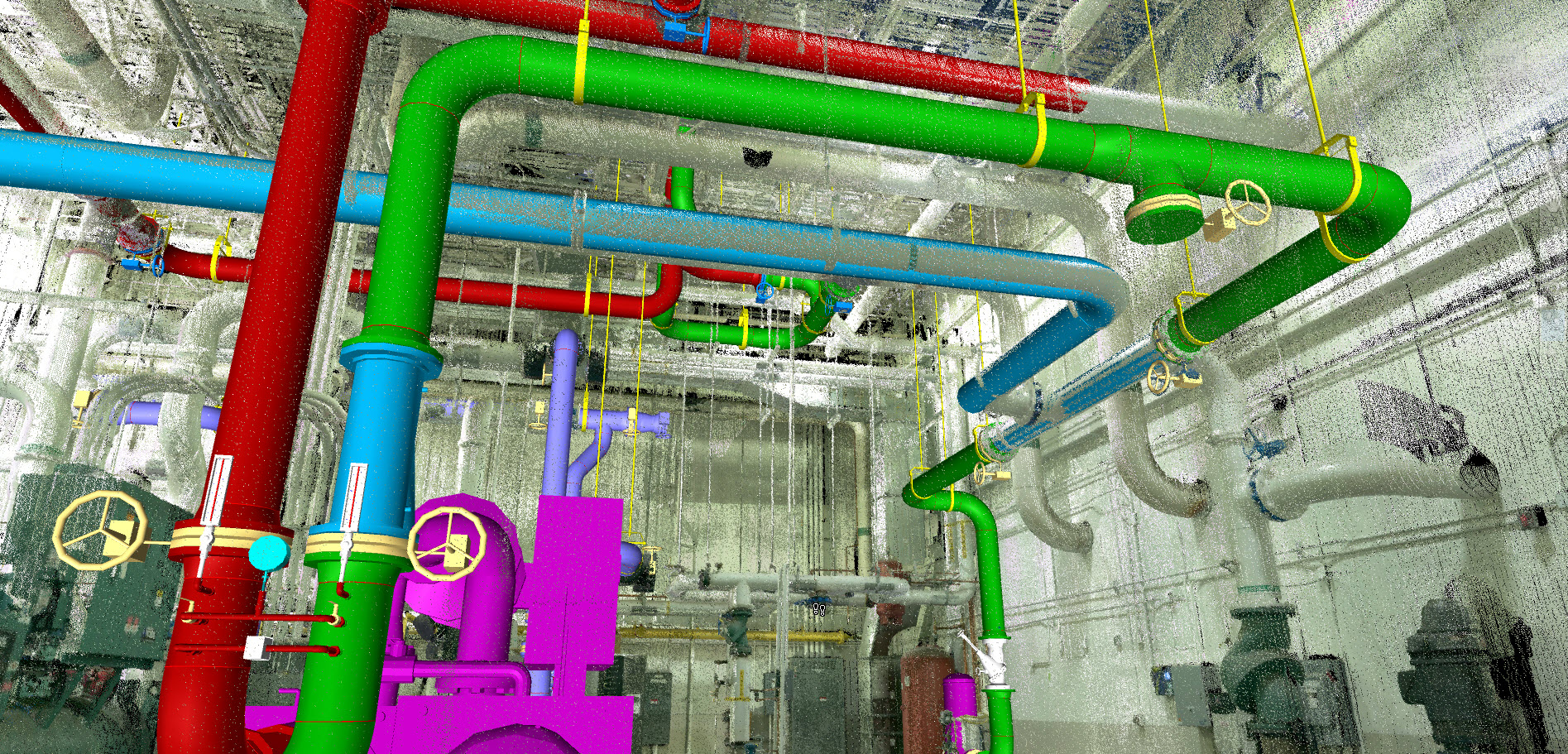

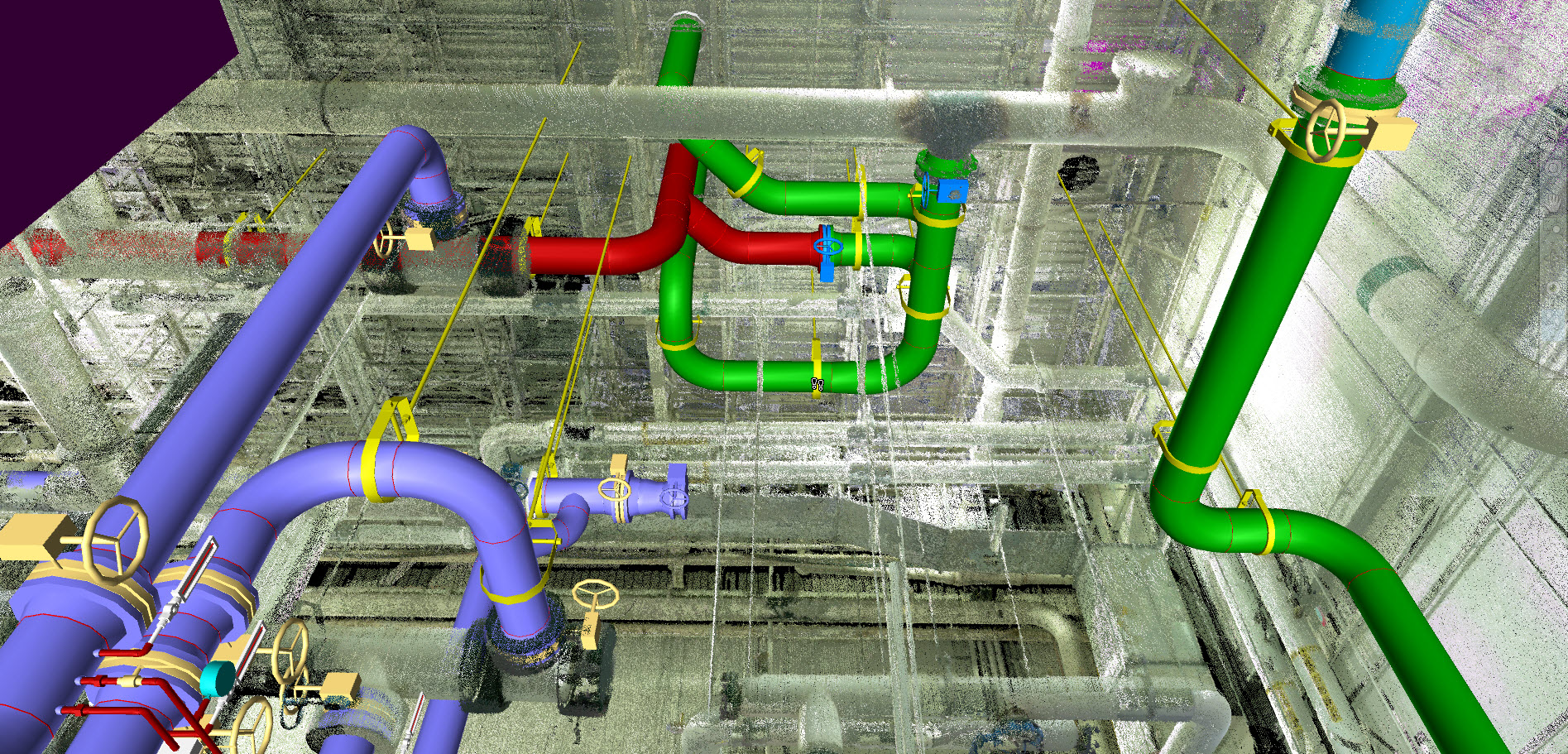

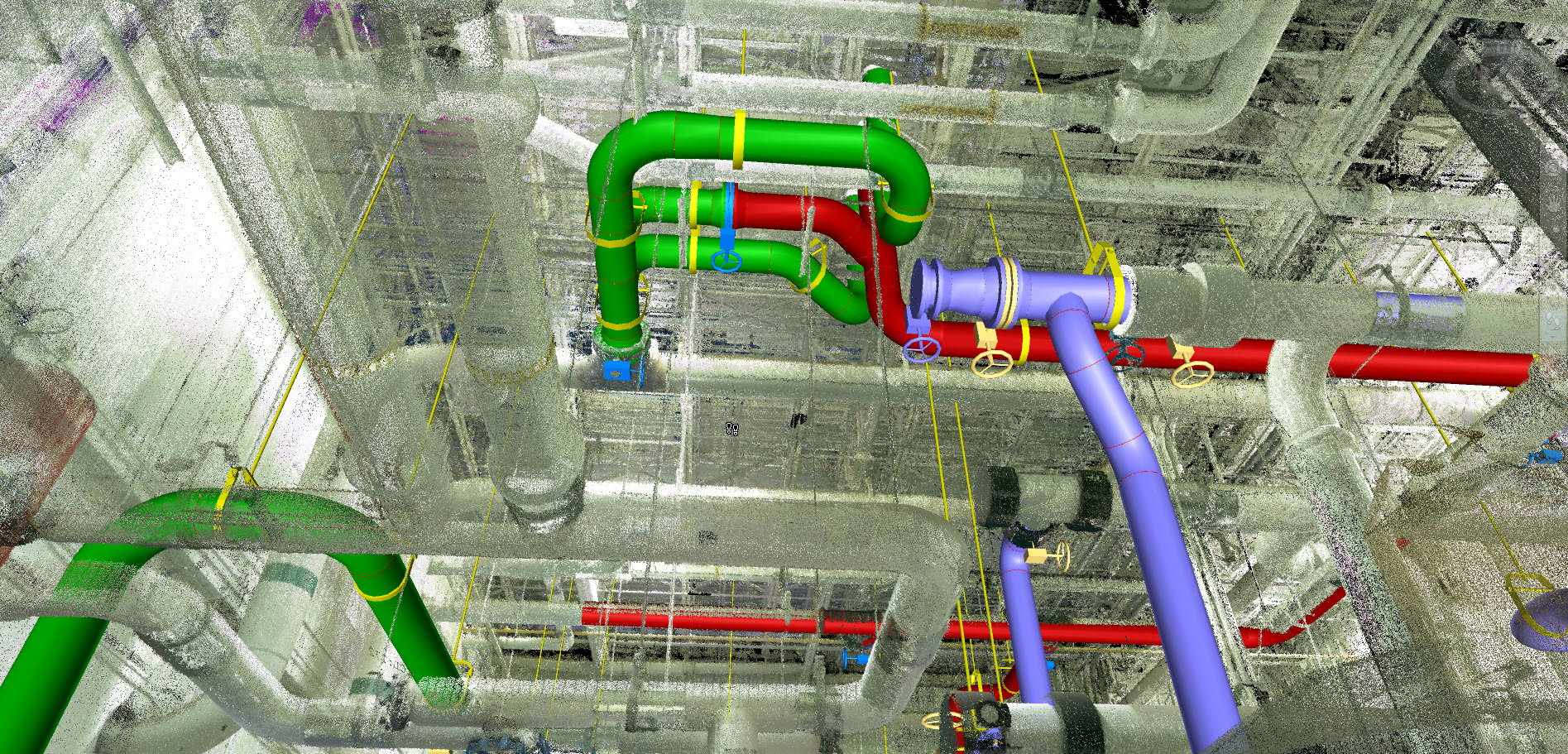

Central Consolidated Inc. installed a 600 ton Centrifugal Chiller, Cooling Tower, Vertical Turbine Pump, and two Base Mounted Pumps, with all the piping and trim for a prominent aircraft manufacturing customer in Wichita, KS. Existing flanged connections, piping and potential obstructions were all located using Laser Point Scanning while 3D Modeling (BIM) was used to pre-plan, adapt and clash detect the Engineer’s original design. This allowed all Piping Spools to be pre-cut, fabricated and painted off site in the controlled environment of our shop. Spools were then installed flange to flange with minimal on-site welding required.

BlogRead the Latest News

Planning Ahead with BIM

- Wednesday, 07 November 2018

Latest Posts

- Job Opportunity – Project Engineer

- Service Employee of the Quarter – Jason Hester

- Featured Employee – Ramon Talamentez

- Heavy Metal Summer Experience

- Job Opportunity – Plumbing/Pipefitter Apprentice

- Job Opportunity – Plumbing/Pipefitter Helper

- Job Opportunity – Service Dispatch

- Featured Employee – Lamont Banks

- Featured Employee – Jim Fortner

- Happy New Year!